Revolutionizing Additive Manufacturing with AlSi10Mg Powder

One of the most popular materials used in additive manufacturing is AlSi10Mg powder. This alloy, composed mainly of aluminum, silicon, and magnesium, offers a range of benefits that make it ideal for a variety of applications in industries like aerospace, automotive, and engineering.

Read more about AlSi10Mg Powder Price here.

Benefits of AlSi10Mg Powder

- Lightweight: Aluminum is known for its lightweight properties, making it perfect for applications where weight reduction is critical.

- Strong and Durable: The combination of aluminum, silicon, and magnesium creates a strong and durable material that can withstand demanding conditions.

- Excellent Thermal Conductivity: AlSi10Mg powder has excellent thermal conductivity, making it suitable for applications where heat dissipation is important.

- Corrosion Resistance: The alloy is highly resistant to corrosion, adding to its longevity and durability.

Applications of AlSi10Mg Powder

Due to its unique properties, AlSi10Mg powder is used in a variety of applications, including:

- Aerospace components

- Automotive parts

- Electronic enclosures

- Heat exchangers

Frequently Asked Questions

Is AlSi10Mg powder suitable for high-temperature applications?

Yes, AlSi10Mg powder has excellent thermal conductivity and can withstand high temperatures, making it ideal for applications where heat dissipation is important.

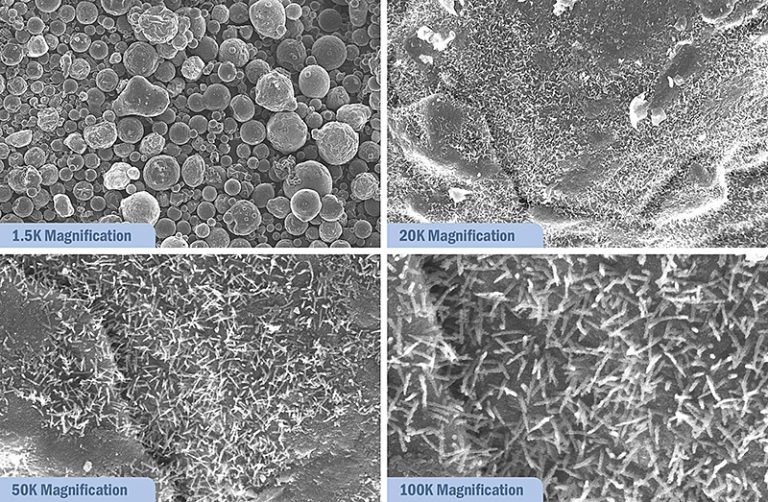

What is the typical grain size of AlSi10Mg powder?

The typical grain size of AlSi10Mg powder is around 50-100 microns, which allows for precise and detailed printing in additive manufacturing processes.

Can AlSi10Mg powder be recycled?

Yes, AlSi10Mg powder is recyclable, making it an environmentally friendly option for additive manufacturing processes.

Overall, AlSi10Mg powder is a versatile material that offers a range of benefits for various applications. Its lightweight, strong, and durable properties make it a popular choice in industries where high performance is essential.