In contemporary architecture and interior design, decorative stainless steel plays a pivotal role in creating visually appealing and durable structures. Whether it’s a sleek high-rise building or a stylish kitchen backsplash, the various stainless steel surface finish options available provide endless possibilities for aesthetic enhancements. Additionally, the introduction of colored stainless steel has broadened the horizon for designers, infusing vibrant palettes into traditionally monochromatic materials.

Exploring Stainless Steel Surface Finish Options

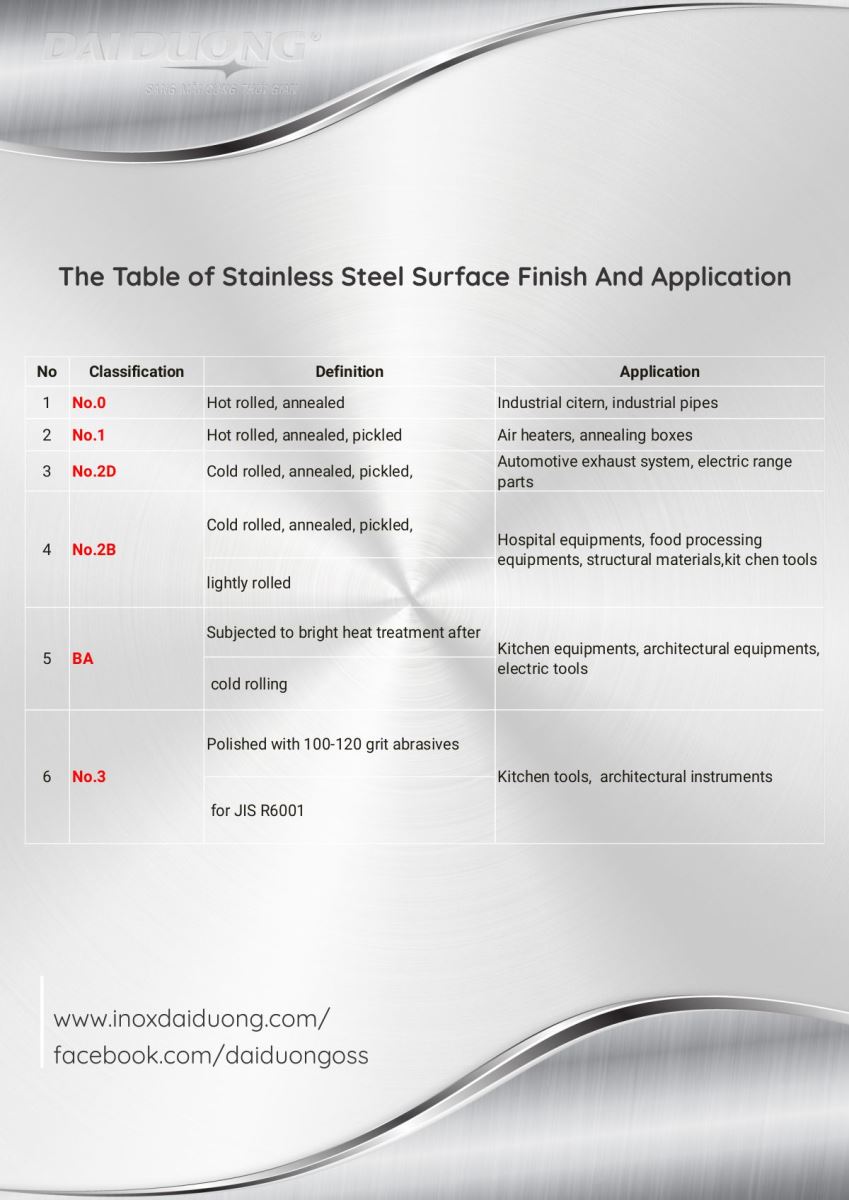

The surface finish of stainless steel significantly impacts its appearance and performance. It determines not only the look and feel but also the material’s resistance to corrosion and wear. Some of the popular stainless steel surface finish options include:

1. Brushed Finish

Known for its uniform linear grain pattern, the brushed finish is widely used in kitchen appliances and architectural paneling. This finish gives a matte look, reducing glare and masking fingerprints and scratches.

2. Mirror Finish

The mirror finish is highly polished to achieve a reflective surface, similar to glass. It adds a touch of elegance and is often used in architectural applications, decorative items, and high-end appliances.

3. Matte Finish

Offering a soft, non-reflective surface, the matte finish is preferred for applications where subtlety is crucial. It is ideal for wall claddings, elevator interiors, and where minimal sheen is desired.

4. Bead-Blasted Finish

This finish provides a textured surface achieved by blasting the stainless steel with fine glass beads. It results in a uniform, matte look that can hide imperfections and provide durability.

The Emergence of Colored Stainless Steel

Traditionally, stainless steel has been synonymous with a silvery-gray tone. However, the advent of colored stainless steel has revolutionized design possibilities. Advanced techniques, such as Physical Vapor Deposition (PVD) and electrochemical coloring, allow stainless steel to take on vibrant hues without compromising its inherent properties.

Read more about colored stainless steel here.

Applications of Colored Stainless Steel

Interior Design

Get more information about stainless steel supplier here.

Imagine kitchen cabinets with a stunning gold sheen or a bathroom vanity in a luxurious bronze. Colored stainless steel makes these visions possible, offering new dimensions to modern interiors.

Architectural Marvels

Skyscrapers and commercial buildings use colored stainless steel panels to stand out in urban landscapes. The ability to use a colorful palette transforms previously dull facades into dynamic artistic statements.

Custom Automotive Parts

The automotive industry benefits from the use of colored stainless steel for both aesthetic and functional components. Custom exhaust systems, trim, and interior details can now match the vehicle’s overall design theme.

Advantages of Colored Stainless Steel

One of the significant advantages of using colored stainless steel is its longevity. Unlike paints and coatings that may fade or chip over time, the coloration process for stainless steel ensures durability. Additionally, colored stainless steel retains all the advantages of its uncolored counterpart, such as resistance to corrosion, ease of maintenance, and a broad range of applications.

Conclusion

With evolving trends in architecture and interior design, the combination of decorative stainless steel, diverse stainless steel surface finish options, and the innovation of colored stainless steel provide endless potential. These advancements not only enhance the visual appeal of various structures and objects but also offer practical benefits that meet the demands of modern design. As these materials continue to evolve, their popularity in diverse applications is set to soar, shaping the aesthetic and functional landscapes of tomorrow.