Power generation, refining, chemical processing, and desalination rely on plates and sheets that withstand pressure, heat, and aggressive media without compromising safety or uptime. Selecting among carbon steel pressure vessel grades and austenitic stainless steels—and knowing when to deploy nickel superalloys—delivers measurable gains in lifecycle cost. From ASTM A516 GR 70 to JIS G4305 SUS304, JIS G4305 SUS316, and the high-alloy family under a240 309s, a240 310s, a240 316ti, sa240 317L, as well as nickel-based materials like Alloy C276 steel plate and Hastelloy C276 steel sheet, each option targets a distinct set of service demands. Understanding where each shines—mechanically, thermally, and chemically—helps engineers spec the right product the first time.

Pressure Vessel Foundations and Versatile Austenitics: ASTM A516 GR 70, JIS G4305 SUS304, and JIS G4305 SUS316

ASTM A516 GR 70 (also written as ASTM A516GR70) is the workhorse pressure vessel plate for moderate temperature service. Normalized fine-grain practice improves toughness and weldability, while minimum mechanical properties—around 260 MPa yield (38 ksi) and 485–620 MPa tensile (70–90 ksi)—support safe vessel design under ASME Section VIII. It is widely used for boilers, separators, and storage tanks in oil and gas, chemical plants, and power stations. The grade accepts standard welding processes, and with proper PWHT selection and impact testing, it is compatible with sour or low-temperature service. When corrosion demands increase, it commonly pairs with stainless steel claddings or corrosion-resistant overlays.

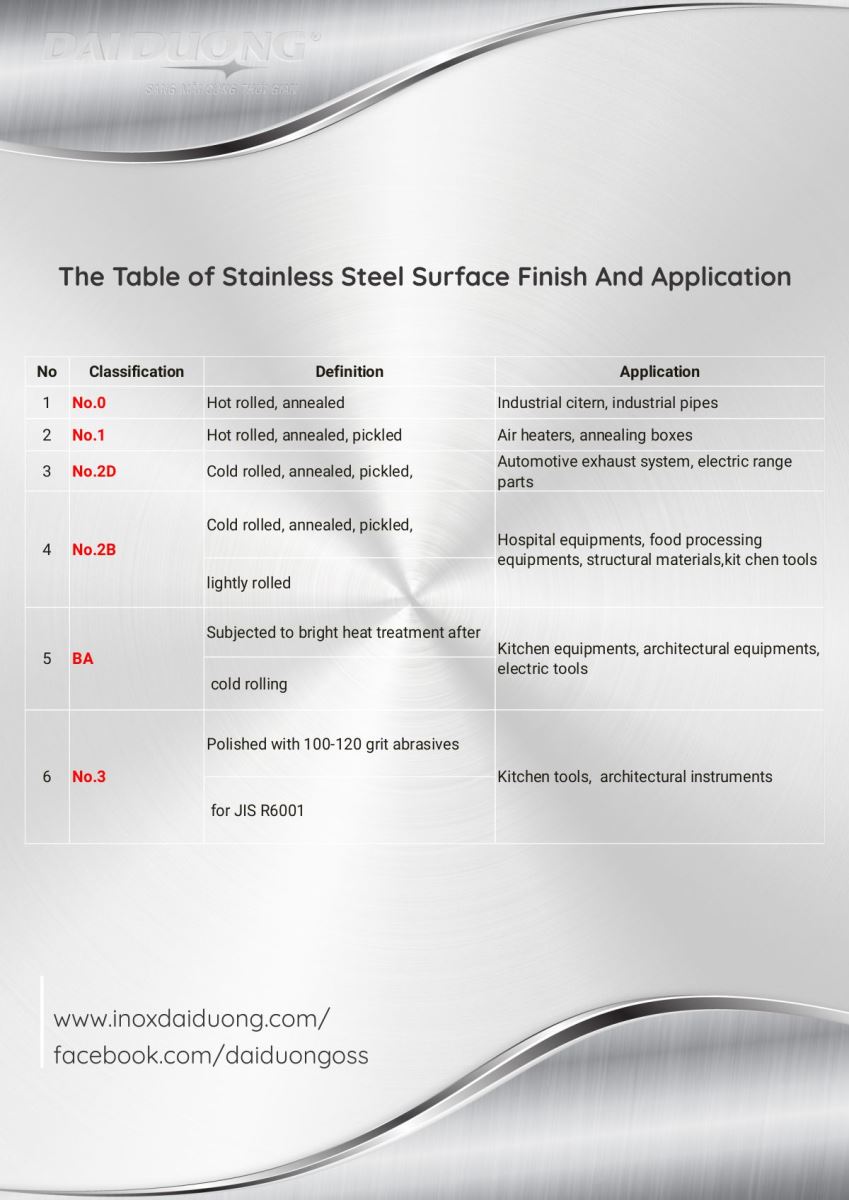

Where corrosion and cleanliness dominate, austenitic stainless steels under the Japanese standard JIS step in. JIS G4305 SUS304 and JIS G4305 SUS316 cover cold-rolled stainless steel plate, sheet, and strip. SUS304, the “18/8” alloy, provides excellent general corrosion resistance, hygiene, and formability. It is a go-to for food equipment, architectural panels, and clean processing lines. SUS316, alloyed with 2–3% Mo, delivers notably better resistance to chlorides and reducing acids, reducing pitting and crevice risk in coastal environments, brine contact, and mild chemical duty. Both grades weld readily and can be supplied with 2B, BA, or polished finishes to suit process cleanliness requirements.

Marrying carbon steel strength and stainless corrosion resistance is common. A shell in ASTM A516GR70 offers cost-effective pressure containment, while an interior cladding in JIS G4305 SUS316 or comparable A240/SA240 grades combats corrosion. This composite approach keeps capital costs in check, reduces the need for aggressive corrosion allowances, and simplifies inspection. In new builds and retrofits alike, engineers use this pairing to extend service life where chloride-laden condensate, caustic wash, or acidic carryover would otherwise shorten equipment intervals.

High-Temperature and High-Moly Options: a240 309s, a240 310s, a240 316ti, and sa240 317L

ASTM A240 (and its ASME counterpart SA-240) governs plate, sheet, and strip for chromium and chromium-nickel stainless steels. Within this family, specific chemistries tailor performance for heat and corrosion extremes. a240 309s is a low-carbon variant of type 309, engineered to resist oxidation and thermal cycling up to roughly 980–1000°C while mitigating sensitization during welding. This grade helps in furnace parts, heat shields, and annealing covers that see intermittent heat where scaling and thermal fatigue are risks.

a240 310s increases chromium and nickel further, offering robust oxidation resistance at continuous service temperatures approaching 1100°C. In burners, radiant tubes, and reformer internals, 310S keeps scale formation in check and retains strength better than lower-alloy austenitics. In atmosphere-controlled furnaces or carburizing environments, alloy selection must account for carbon pickup; protective coatings or alternate materials can be considered where carbon exposure is severe.

Not all high-temperature challenges are about oxidation. Sensitization during long exposures between 450–850°C can precipitate chromium carbides at grain boundaries, undermining corrosion resistance. a240 316ti stabilizes 316 with titanium, tying up carbon so welded or heat-affected zones resist intergranular attack. This makes 316Ti valuable in systems that see repeated thermal cycling—like exhaust scrubbers or hot wash lines—where a traditional 316L might still be at risk due to operational dwell at sensitization temperatures.

For aggressive chloride chemistry without extreme heat, sa240 317L extends molybdenum beyond 316L, boosting pitting resistance. Using the PREN metric (PREN = %Cr + 3.3×%Mo + 16×%N), 317L often lands in the high 30s depending on exact chemistry, while 316L typically sits in the mid-20s. That uplift translates into higher critical pitting temperatures in brine exchangers, bleach plants, and paper mill liquor circuits. In practice, 317L reduces the frequency of crevice-related failures in gasketed joints and tube-sheet interfaces, particularly where stagnant chlorides concentrate. Fabricators appreciate that these A240/SA240 grades maintain weldability and formability, enabling efficient vessel heads, shells, and tube sheets without sacrificing performance.

Nickel Superalloy Defense Against the Worst Chemistries: Hastelloy C276 and Field-Proven Examples

When mixed acid streams, chloride oxidizers, or reducing media overwhelm stainless steels, nickel-molybdenum-chromium alloys step in. Hastelloy C276 steel sheet—UNS N10276, commonly called Alloy C-276—balances high nickel with molybdenum, chromium, and tungsten to resist localized and uniform corrosion in harsh conditions: hydrochloric acid, sulfuric acid with chlorides, acetic and formic acids, wet chlorine, hypochlorite, and chlorine dioxide. Its microstructure and controlled carbon and silicon minimize carbide precipitation, preserving corrosion resistance after welding. With proper procedure and matching filler, C-276 fabrications maintain integrity in crevices and weldments where lesser alloys fail.

Beyond chemistry resistance, C-276’s immunity to chloride stress corrosion cracking outclasses most austenitic stainless steels. In bleach plants, FGD systems, and brine concentrators, this resistance translates to fewer unplanned outages and longer inspection intervals. Solution annealing (around 1120°C followed by rapid quench) restores optimal corrosion performance after severe cold work or heavy welding. Machining and forming are manageable with appropriate tooling and work hardening awareness, but expect lower cutting speeds than stainless steels due to the alloy’s strength and work-hardening rate.

Case studies reinforce the selection logic. In flue gas desulfurization absorbers, stainless steels like sa240 317L may perform well in controlled pH zones, yet crevice-prone areas exposed to chloride-laden slurry often upgrade to C-276 to prevent under-deposit attack. Offshore, a sour water stripper can leverage a cost-effective ASTM A516GR70 shell with a corrosion-resistant overlay and critical internals in Hastelloy C276 steel sheet for trays and downcomers, securing resistance to H2S, chlorides, and variable pH. In phosphoric acid evaporation, 316L and even 317L can succumb to fluoride-containing streams; C-276, with its molybdenum and tungsten synergy, holds crevice corrosion at bay, protecting baffles and heat exchange surfaces.

Material strategy often blends families. A vessel might combine a ASTM A516 GR 70 pressure boundary, a a240 310s or a240 309s hot zone liner for oxidation resistance, and C-276 nozzles or splash zones where turbulence and chlorides concentrate. Heat exchangers may specify JIS G4305 SUS316 or JIS G4305 SUS304 for shells, with upgraded tube sheets in sa240 317L and select tubes in C-276 for the worst fouling lanes. This layered approach optimizes both capex and opex: stainless steels carry the bulk of duty economically, while nickel alloys defend high-risk locales where failure costs are disproportionate.

Practical procurement considerations round out the decision. A516 plates are widely available with multiple impact test regimes and thickness ranges suitable for large shells. A240/SA240 stainless plates and sheets offer surface finishes that aid cleanability, crucial for hygienic or high-purity service. Nickel alloys like Alloy C276 steel plate are stocked in strategic thicknesses; early engagement with mills helps align heat schedules, NACE or ASTM supplementary testing, and delivery windows. Clear specification—chemistry limits, delivery condition, heat treatment, NDE, and corrosion testing—ensures materials arrive ready for fabrication and compliant with design code and process risk.